Take the belowactions to avoid electrode break up, trip and over-oxidation during steelmaking

Adjust the phase sequence of electrodes. In the three-phase electric arc fumace, the phase sequence should be right of anticlockwise. Breakage will happen because of the loosing taken place because of the clockwise sequence.

Reduce the factures and breakages because of external mechanical force.material collapse in the fumace and improper operation. Load large pieces of steel material in the lower level of the fumace and distribute the scrap evenly.

Avoid non-conductive materials in the scrap; don’t put lime and other non-conductive objects gathering just right under the electrodes.

Attention to the lid position; Align the electrode columns with the roof hole and keep the electrodes column in parallel. Always keep the roof hole wall clean in order to avoid the accumulation of residual slag.

Maintain the furace tilting system in good condition so the fumace tilting remain stable.

Avoid clamping device holds electrode junction and nipple joint.

Protect the end faces of electrodes. Avoid bad connection because of end faces oxiclation and embed foreign object.

Protect the tips of electrodes and nipples thread from mechanical damage before and during connecting of electrodes.

Prevent slag or foreign objects embedding the surface of electrodes and nipples which will affect the threading in; blow the surface with compressed air before connection.

Reduce the consumption of oxidation of the electrode perimeter to enhance the sealing of the fumace in order to reduce air intrusion. Minimize the exposure time of the hot electrodes outside the fumace. Appropriate operation of oxygen blowing.

Selecet nipple of good quality and good machining accuracy, avoid mixed using nipples from several suppliers.

Suggest to take spray cooling technology for melfing fumace; it can effectively reduce the oxidative consumption of the surface of electrodes.

About us

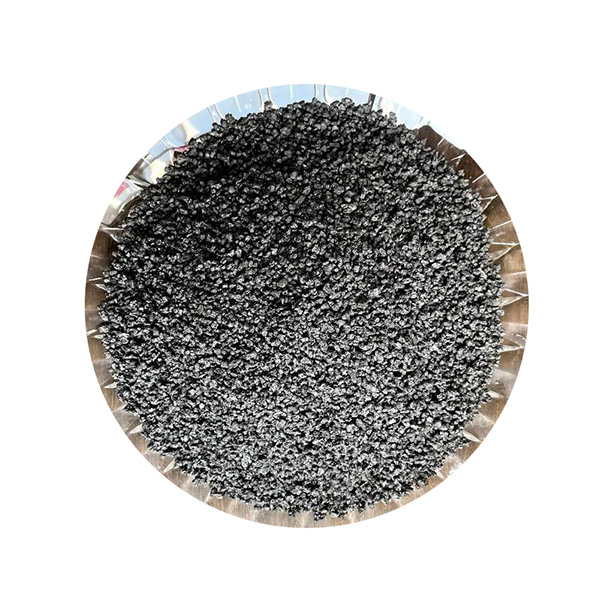

BENHONG is a professional manufacturer, specializing in the field of graphite electrodes. With various products, the specifications of graphite electrode range from 100 mm to 700 mm in diameter. Our RP graphite electrodes have various specifications, These products always have three types of lengths, including 1800 mm, 2100 mm and 2400mm. If user has special requirements, please contact us.

1.30 years of production experience has convinced us that this is our careers, not just a business.

2.We have all the certificates needed in the field:ISO/SGS/MSDS.

3.Our team is honest, united and has a high service spirit.

4.We have establaished cooperation with Saudi Arabia,Iran,India, Turkey, Brazil, Russia and other countries.

5.Customer as the core of the complete after-sales service.

6.The repeat purchase rate exceedns 92%.